As another year is upon us, we thought we’d take a look at our top 5 moments from across The Shearline Group of 2022.

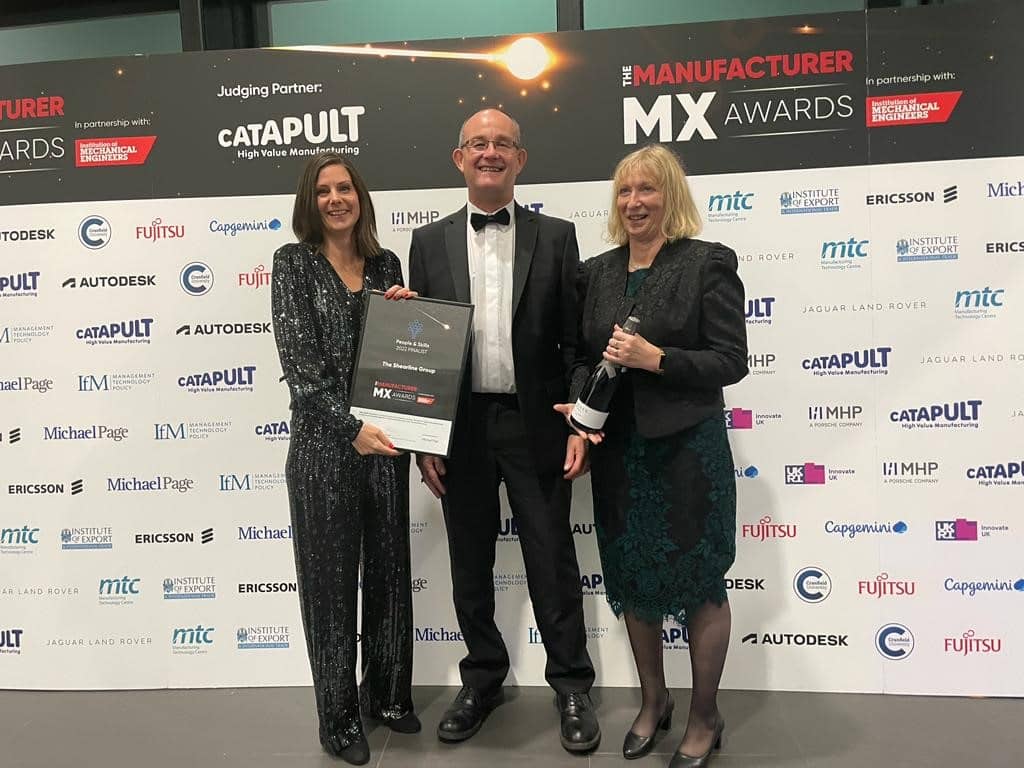

Throughout last year, we took off our steel toe caps and dusted off our black ties to attend the finals of several award ceremonies.

From the local Cambridge Independent Science and Technology Awards in May to the UK’s largest and most rigorous industry awards programme: The Manufacturer MX Awards (TMMX Awards), in November.

We may not have been crowned winners, but we’re proud to have reached the shortlist of such reputable awards. Watch this space for 2023!

Our online presence was long overdue a refresh, and in 2022 we went live with 3 new websites:

Shearline Precision Engineering

Now showcasing our full range of subcontract manufacturing services, links to meet the team alongside an updated careers page and information for Apprentices who are thinking of joining our renowned Apprenticeship scheme – we’re really pleased with the new sites.

We’re now working on a Shearline Group website which will tie all three divisions together, and this is due to go live later this year.

“There’s no bad time to invest…”

Our founder, David Littlechild, has built The Shearline Group to where it is today by following this principal (among many others!) Our investment programme sustained its pace in 2022.

All departments within The Shearline Group took receipt of new equipment throughout the year.

From a new Doosan vertical machining centre with an impressive 2.1 metre X-axis to the latest evolution in 20mm sliding head machining: the Star SR-20JII Type B sliding head lathe.

SXL took delivery of a state-of-the-art Coordinate Measuring Machine, a Mitutoyo CRYSTA-Apex which provided the much needed, additional inspection resource to support the ever-growing order book.

Bolstering our sheet metal folding services, the high speed Trumpf TruBend 7050 was delivered in December – perfect for our small and medium sized components.

In subcontract precision engineering, time is money and to remain at the top of our field, we’re dedicated to keep investing in latest technologies to support all facets of our precision manufacturing facilities.

We love inviting new potential customers into our factories: there’s no better way to understand what we can offer than being surrounded by our machines and talking to our people. We had a record number of new customers visit us in 2022. We’re honoured to be working closely alongside many of these customers this year, supporting their supply chain requirements across a wide range of industries.

We have an open-door policy at Shearline, so if you’re looking for a new sub-contract manufacturing partner, give us a call and arrange a visit. We’d be delighted to show you around!

Crucial to the success of last year was the dedication of our employees.

Our goal is to be the best, and remain the best, manufacturing employer in East Anglia. Testament to this, is the fact that many of our employees celebrated significant work anniversaries last year, upon which long service awards were handed out.

Three Apprentices joined the Shearline Group and started their manufacturing careers via our Apprenticeship scheme. In parallel, we offered internal promotions to several employees as a result of their hard work and dedication to The Shearline Group.

It goes without saying that our focus remains firmly on supplying quality precision components and precision assemblies to all our customers, old and new. Customer satisfaction last year was 100% and we’re striving to repeat this, this year.

Last but not least… 2023 marks Shearline’s 50th year in business and we’ve got events lined up in the calendar to celebrate and share this success with our employees, customers and suppliers.