In the dynamic world of machining, Lights Out Running has emerged as a revolutionary concept gaining widespread popularity, especially in tandem with the increase of artificial intelligence in our surroundings. This approach involves minimal to no human intervention in machining operations, offering advantages for manufacturers. Here, we’ll delve into the growing appeal of Lights Out Running in the machining industry, shedding light on some of the benefits and how Shearline strategically embraces this technology to deliver exceptional results for its customers.

Maximizing Operational Efficiency: Lights Out Running allows machining processes to continue uninterrupted, 24/7. This results in a significant boost in operational efficiency as machines can operate during non-working hours without the need for constant human supervision. Shearline’s commitment to maximizing efficiency aligns seamlessly with the lights out running philosophy as it streamlines processes, improves production speed by reducing downtime, and enhances overall effectiveness to achieve the best possible results.

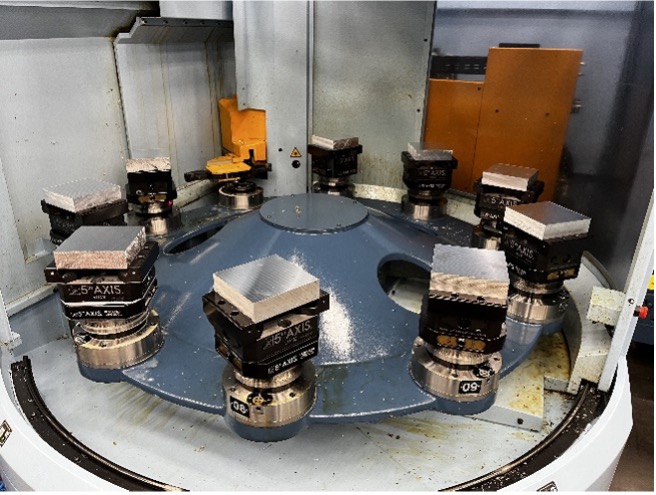

Tom Biscoe, Cell Leader for 5th Axis section at Shearline was keen to talk about this exciting technology

“The ability to get through work at a much faster rate free’s up our machines giving us extra capacity for our customers and shorter lead times.

Utilising Lights Out Running for a job this week meant the machining hours reduced by 60 hours!

Cheaper and faster but still great quality is probably the best thing to our customers ears!”

Improved Consistency and Quality: Automation in lights out running ensures consistent machining parameters and precision. Shearline’s implementation of this technology is designed to deliver superior quality products with minimal variability, meeting and exceeding customer expectations.

Optimizing Energy Consumption: Lights Out Running promotes energy efficiency by allowing manufacturers to schedule machining processes during off-peak hours when energy costs are lower. Shearline’s commitment to sustainability is evident in its strategic use of lights out running to optimize energy consumption and reduce environmental impact.

Adaptability and Scalability: Shearline’s implementation of lights out running is designed to be adaptable to various machining operations. Whether it’s a small batch or large-scale production, the technology seamlessly scales to meet the specific needs of the customer.

As the manufacturing landscape continues to evolve, embracing innovations like Lights Out Running becomes essential for staying competitive. Shearline’s commitment to harnessing this technology highlights its dedication to providing customers with the very best in terms of efficiency, quality, and overall excellence in the machining world.