Sliding head machining, also known as Swiss-style machining, offers several benefits over traditional machining methods.

Sliding head machines are designed to provide high levels of precision, with tight tolerances and smooth surface finishes. This makes them ideal for producing complex, high-precision parts.

Sliding head machines are highly efficient, with fast cycle times and the ability to produce parts in large quantities. This makes them ideal for high-volume production runs.

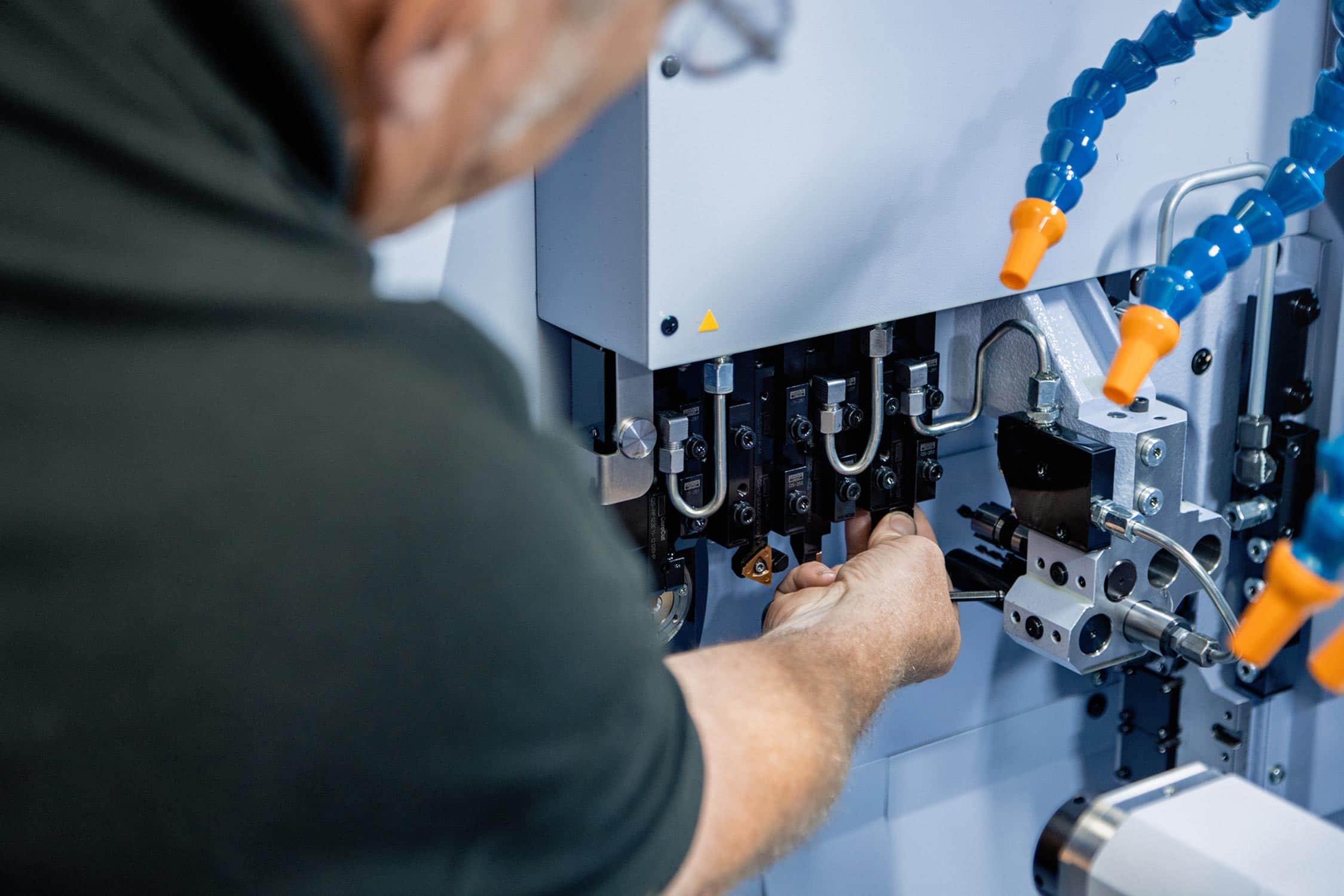

Our newest sliding head machine: the Star SR-20 lathe is producing tens of thousands of components 24/7. See the machine in action here!

Sliding head machines are highly versatile, with the ability to handle a wide range of materials and part geometries. This makes them ideal for producing a variety of different parts with minimal setup time.

Sliding head machines are designed to minimise waste by using bar stock as the raw material. This reduces scrap and material costs, resulting in cost savings for The Shearline Group, which are then passed on to our customers.

Sliding head machines are highly automated, requiring minimal operator intervention. This reduces labour costs and increases productivity, ensuring that your component piece pricing remains as low as possible.

Overall, sliding head machining offers a range of benefits that make it an ideal choice for high-precision, high-volume production runs.

If you’ve got a component which you need manufactured in high volumes, speak to us today to find out if one of our state-of-the-art sliding head machines is the best route for the job!