Powder coating is a dry finishing process that involves electrostatically applying a fine powder to a metal surface, which is then heated to melt and create a smooth and even coating. On the other hand, wet spray painting involves using a liquid paint that is applied to a surface and then allowed to dry and cure. While both methods can provide a protective finish, powder coating offers several advantages that make it the superior choice.

Durability is one of the key benefits of powder coating. The melted and fused powder creates a tough and resilient coating that is highly resistant to chipping, cracking, peeling, and fading. This makes it ideal for products that are exposed to harsh environments or heavy use. In comparison, wet spray painting can be more prone to wear and tear over time, resulting in frequent touch-ups or reapplication.

We supply powder coated components to customers spanning a wide range of industries – some of these have an end application in harsh environments, including defence and aerospace. Our powder coat finish is tried, tested, and approved!

In fact, some of our customers have completed durability trials using our powder coated finish, and as a result – have changed their drawings to reflect a powder coat paint, instead of a wet spray finish.

Versatility is another strength of powder coating. It can be applied to a wide range of materials, including metal, aluminium, steel, and even plastic, and can be customised to achieve various textures, gloss levels, and colours. Wet spray painting, on the other hand, may have limitations in terms of coating certain materials or achieving specific finishes, which can affect the final appearance and quality of the product.

Efficiency is a notable advantage of powder coating. It minimises waste and overspray, as the excess powder can be collected and reused, reducing material costs and environmental impact. Powder coating also requires less drying and curing time compared to wet spray painting, resulting in faster production turnaround and shorter lead times. In contrast, wet spray painting may require longer drying and curing times, which can slow down the production process and increase costs.

Environmental friendliness is an important consideration where powder coating shines. Powder coatings are typically free of volatile organic compounds (VOCs), which are harmful pollutants that can be released into the air during the drying and curing process of wet spray painting. This makes powder coating a greener choice for businesses and individuals who prioritise sustainability. Additionally, the overspray from powder coating can be easily collected and recycled, reducing waste, and minimising the environmental impact.

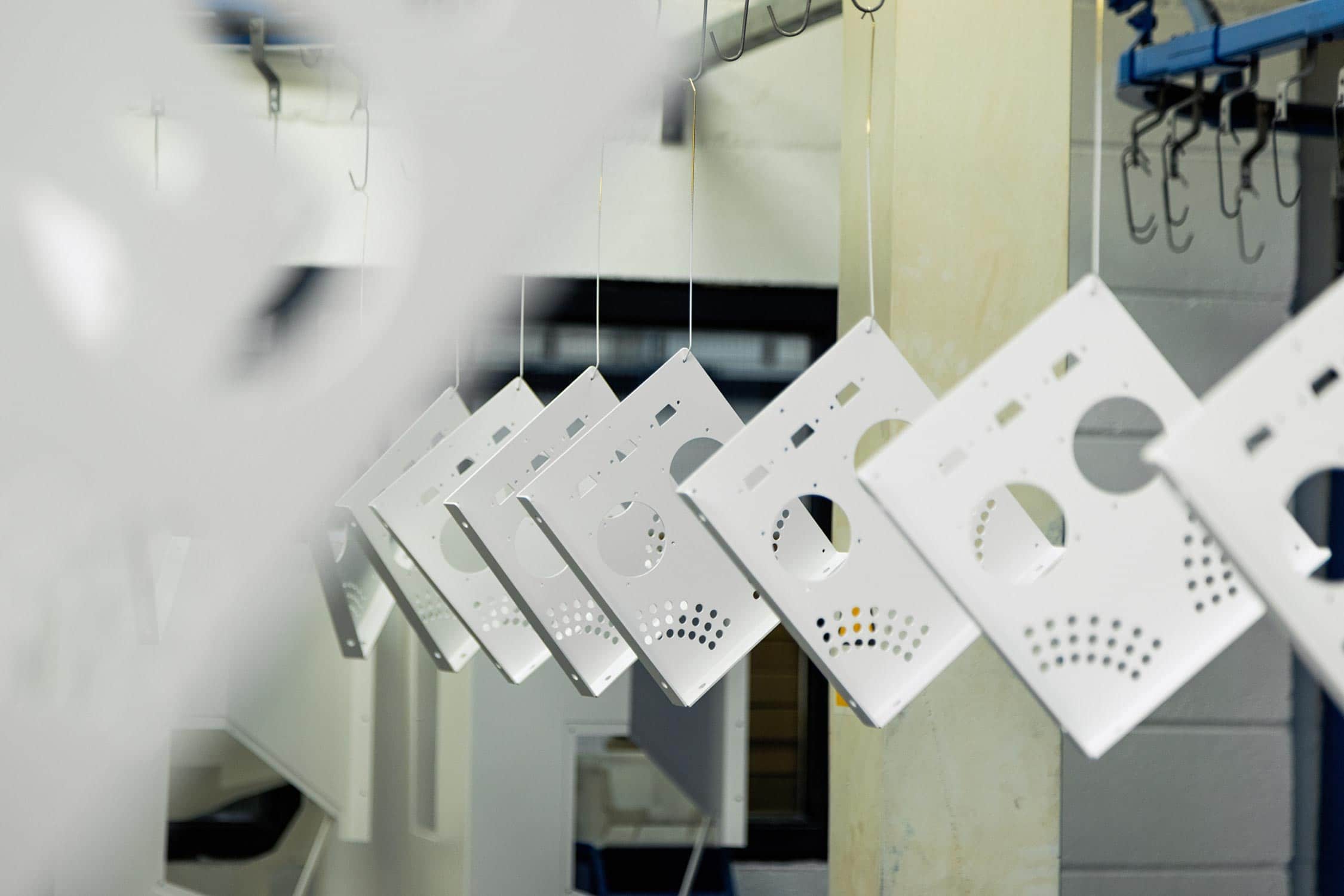

At The Shearline Group, our state-of-the-art facility is equipped with the latest powder coating technology, enabling us to provide high-quality finishes that meet the highest industry standards. Our experienced team of professionals is skilled in handling various materials and products, ensuring that your components receive the best treatment possible.

In conclusion, powder coating offers numerous advantages over traditional wet spray painting methods, including durability, versatility, efficiency, and environmental friendliness. Choosing our powder coating facility for your finishing needs guarantees a superior service that delivers exceptional results. Experience the benefits of powder coating by contacting us today and learn why we are the best choice for your Fabrication, machining, assembly, and complete manufacturing projects.