“I left school with no qualifications and being dyslexic, reading and writing were always a challenge for me. Luckily, my parents bought our family home from Dan Morley, who owned a local Precision Engineering Company and Garage, and he invited me to start an apprenticeship.

I nervously went along for an interview and they took me on. I was seriously daunted by the prospect of spending one day at college each week but the fantastic teacher said “boy, as long as I can understand what you’ve written down, that’s alright”. A huge weight lifted and combined with the freedom Dan gave me to explore the machines, I blossomed. I think it is common for people with dyslexia to be talented in other, more practical or creative areas.

So I guess you could say, engineering was really just a lucky accident and fortunately it was something I had a natural talent for.”

“I wanted to continue my education in engineering but Dan Morley was bought out, and I no longer had the day release for college. A blessing in the long run as I got a new job at the Cambridge University Engineering Labs. Again, it was such a wonderful place to learn. Meeting all these professors and bright students doing various engineering projects, it was so inspiring. I soon got a very good reputation and was given prestigious jobs to do including investigating the dynamics of machine tools and visiting various big engineering companies. Progression within the engineering department required a degree and that was never going to happen so I made the decision to start my own business.”

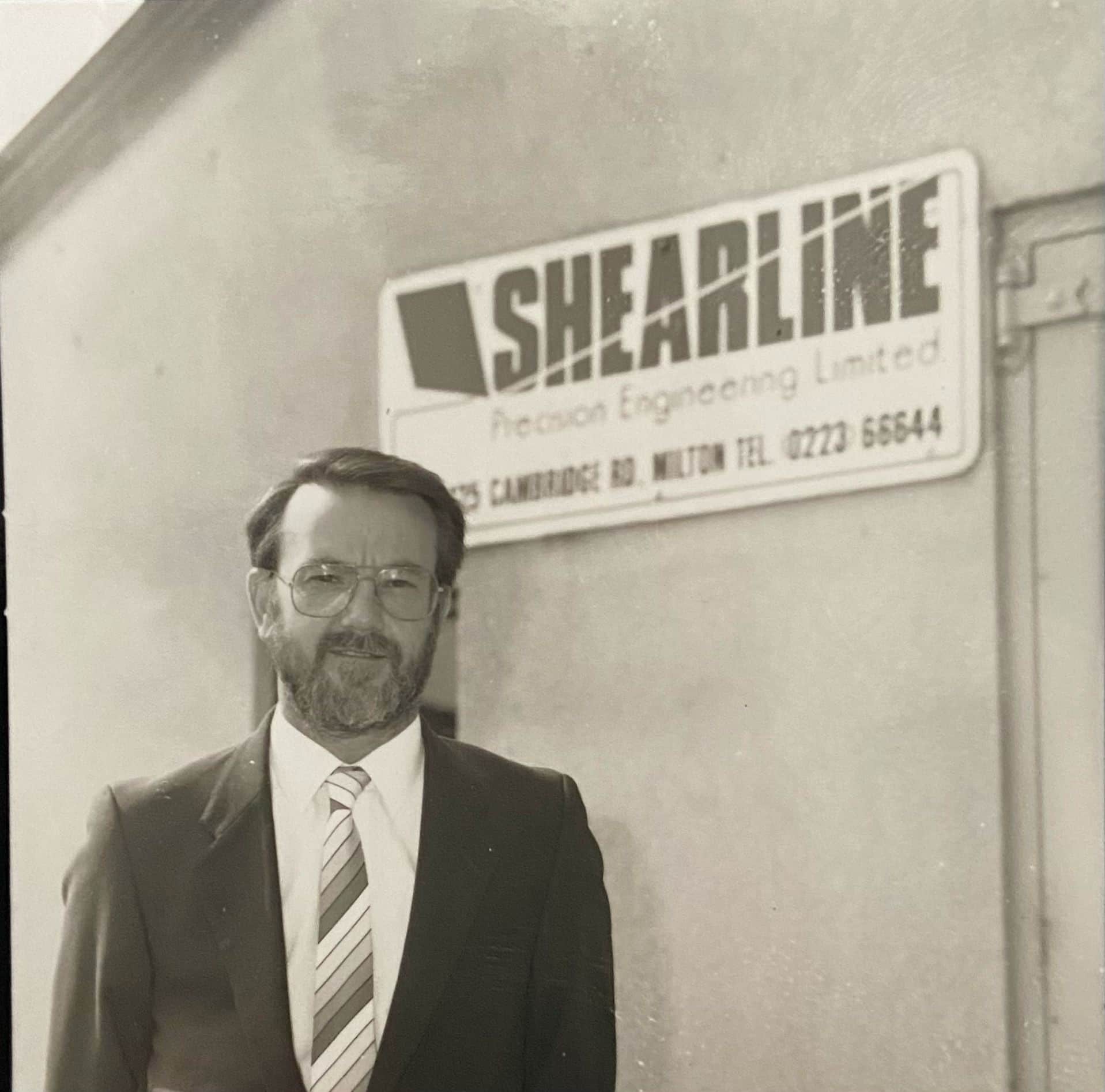

“It was actually called DHL when I first started – I wished I had registered that before the big DHL moved to the UK! My brother John introduced me to the glass blowing company TW Wingents while I was still at Cambridge University Engineering Labs. They wanted some gas jets for their blow torches so I started making some on a little lathe in my parents’ summerhouse. It didn’t take long before I rented a tiny place of TW Wingents in Milton. I had 3 or 4 machines and a desk – that is where it all started.”

“Yes, not long after Shearline (as it was now known) moved to Water Street in Chesterton, my brother John and I also established a flash lamp manufacturer at the Cambridge Science Park – Noblelight. John was the brains and I brought engineering knowledge and entrepreneurial flair, so we worked well as a team. The time came when I wanted to focus all my efforts on Shearline, so we parted ways and I used my share of the payout towards building our state of the art factory in Ely.”

“There are so many things! That Shearline grew from a tiny shed to what it is today is a huge achievement. Also, that we have been able to contribute to the growing science and medical industries in the Cambridge area. When I think about all the applications our manufactured components have gone in to, it is something I am incredibly proud of.

I have always been very aware of our responsibility to minimise our impact on the environment so investing in green technology and embedding processes to reduce and reuse materials; long before environmental safeguarding was at the forefront of people’s minds.”

“I think I should have been more inquisitive. Sometimes I have been overly trusting and there have been a few occasions where I should have taken my rose tinted glasses off. But on the whole, I don’t have many regrets when it comes to Shearline. I am incredibly proud of what it has become.”

“I think because of the positive experience I had as an apprentice, supporting people through training and apprenticeships has always been at the core of Shearline. We have a number of apprentices who are still with us after 25+ years and I am certain that Shearline’s success is down to the commitment and continued growth of the people who make it.”