When you’re choosing a manufacturing partner, ISO certifications often come up, but what do they really mean for you as a customer? In this blog, we’ll break down the key certifications you’re likely to see in precision manufacturing and explain why they matter when it comes to quality, reliability, and trust.

ISO stands for the International Organization for Standardization – an independent body that sets global standards for products, services, and systems.

When a manufacturer is ISO certified, it means their processes and procedures have been externally audited and verified to meet internationally recognised best practices.

In short: it’s proof that the company doesn’t just say they care about quality, they back it up.

What it covers:

ISO 9001 is the world’s most widely recognised quality management standard. It ensures companies follow consistent, structured processes that focus on meeting customer needs, regulatory requirements, and continual improvement.

Why it matters to you:

What it covers:

AS9100 builds on ISO 9001 but adds stricter requirements for aerospace, defence, and high-reliability industries. It covers everything from risk management to traceability to specific controls for safety-critical components.

Why it matters to you:

What it covers:

ISO 14001 focuses on a company’s environmental impact, requiring them to actively manage waste, energy usage, and pollution, and commit to ongoing environmental improvement.

Why it matters to you:

What it covers:

ISO 13485 is a specialist quality standard for companies manufacturing medical devices or components. It focuses heavily on risk management, regulatory compliance, and patient safety.

Why it matters:

Note: Not held by Shearline, but important for specific medical applications

Choosing a manufacturing partner with relevant ISO certifications offers you more than just a badge, it gives you real benefits:

In today’s competitive landscape, these things aren’t just nice to haves, they’re essential.

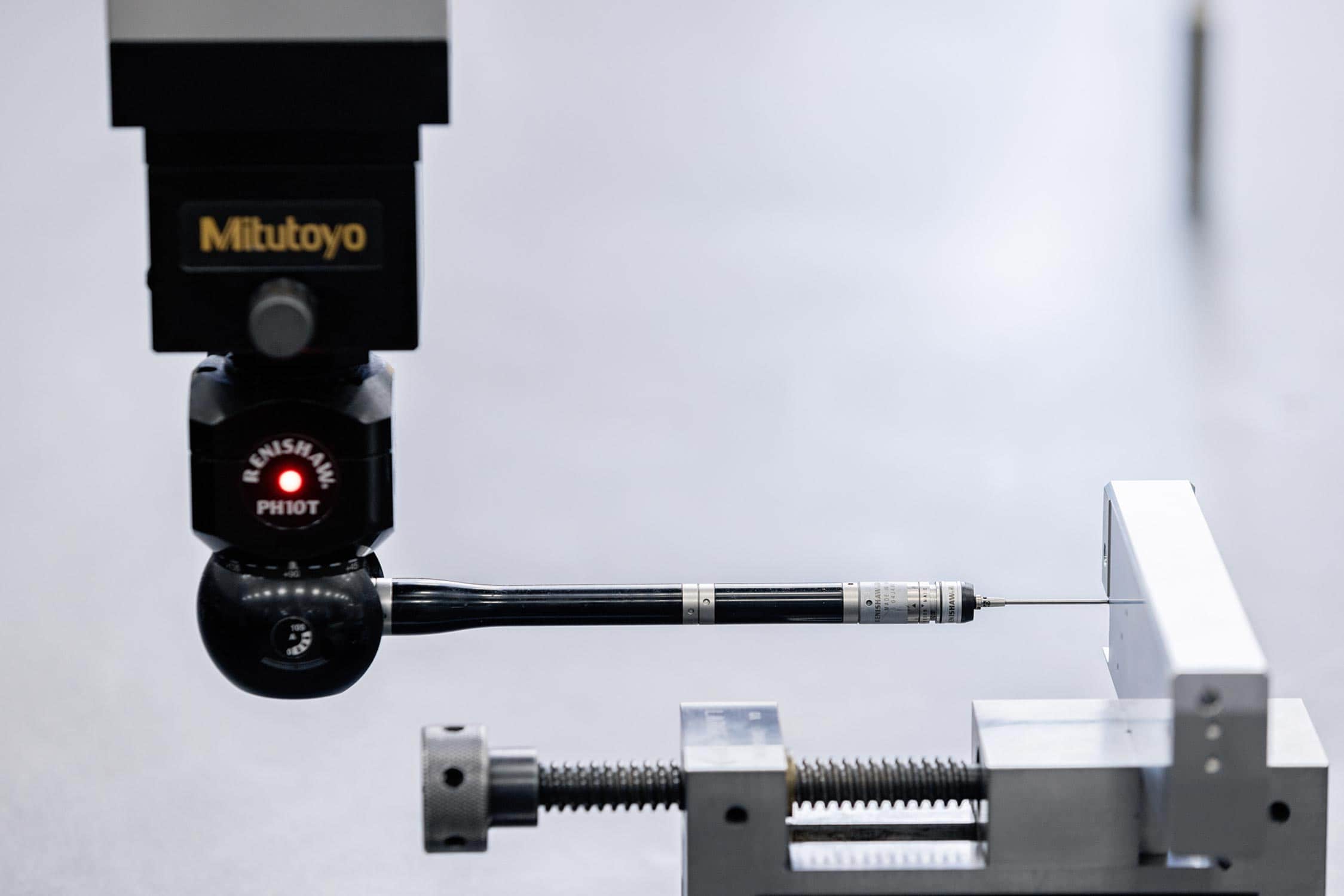

At Shearline, we’re proud to hold ISO 9001, AS9100, and ISO 14001 certifications, reflecting the standards we uphold every day across our precision machining, fabrication and assembly services.

Whether you’re working in aerospace, defence, or other high-spec sectors, we deliver consistent quality, robust traceability, and a proactive approach to continuous improvement.